-

Mobility

Mobility

Using aluminum alloys that are lightweight yet offer optimal yield strength and excellent durability, we develop key components for not only ICE and hybrid vehicles but also electric and hydrogen vehicles. These include damper pulleys for engines, steering components, battery cases, HVAC core components, inverter cooling plates, and ultra-high-pressure safety valves for hydrogen tanks. All are developed based on comprehensive deformation and extrusion analysis using Deform software to ensure 100% customer satisfaction.

Additionally, our rapid development system enables validated component application for next-generation mobility sectors such as UAM, autonomous vehicles, and eco-friendly yachts. We guarantee durability even in extreme environments such as cryogenic and ultra-high-pressure conditions by utilizing specially developed aluminum composite materials tailored for each use.

-

Marine & Plant

Marine & Plant

Based on the characteristics of aluminum alloys—excellent corrosion resistance and superior durability under extreme fatigue and fracture conditions—our components are ideal for membrane structures that prevent sloshing in LNG, LN2, LH2, and methanol transport vessels. Other applications include frames for solar panels, scaffolding components for construction sites requiring both lightness and safety, and piping connectors in chemical process equipment. We also supply high-quality heat sink systems and enclosures for a wide range of industrial needs at competitive prices through a reliable supply chain.

-

Defense Industry & Advanced Future Components

Defense & Advanced Future Sectors

With rapid advancements in ground and naval weapon systems—such as missile launchers, radars, self-propelled guns, and amphibious armored vehicles—and the rise of drones as strategic assets, aluminum alloys are playing a pivotal role as game-changing materials.

Leveraging advanced manufacturing technologies, we develop parts using low-density, high-solubility A8000-series composite materials, which are highly effective in weight-to-strength performance. These materials are also suitable for aerospace applications. Furthermore, due to their biocompatibility and corrosion resistance, aluminum composites are gaining attention as alternatives to expensive titanium in biomedical implants. We are continuously expanding into future advanced material sectors through dedicated research and development.

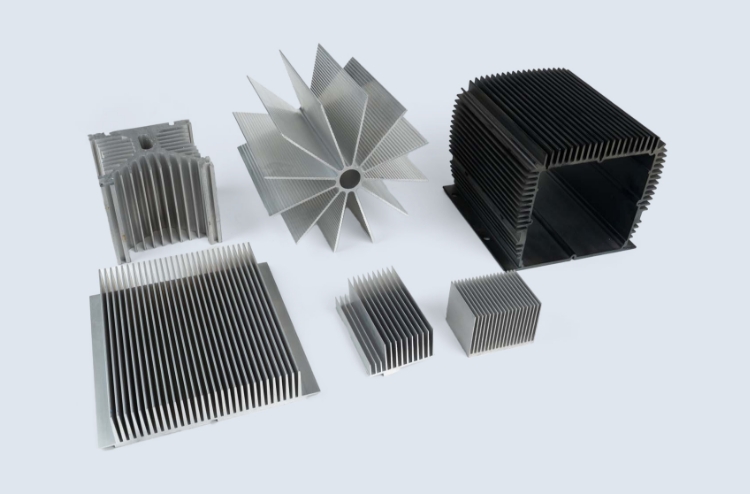

Heat Sink

- Material

- A6063-T5

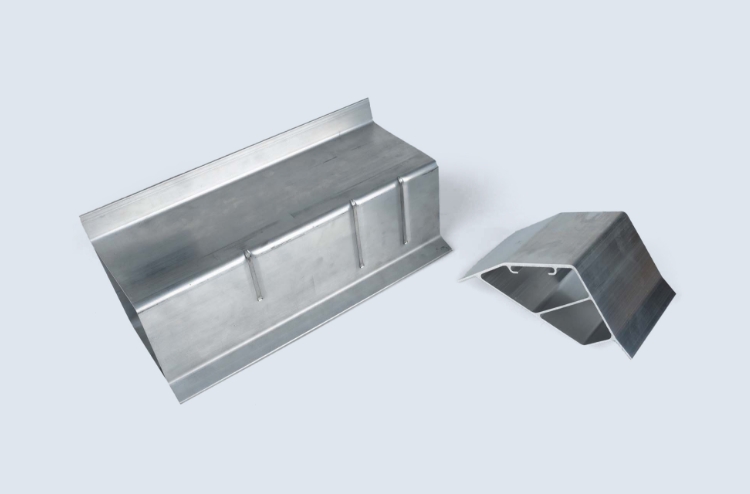

Side Beam for EV

- Material

-

A6N01-T5

A6082-T6

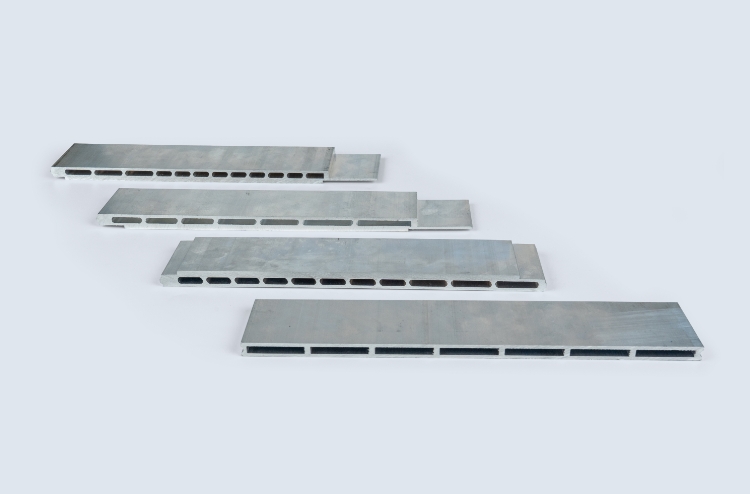

Cooling Plate for EV

- Material

- A6N01-T5

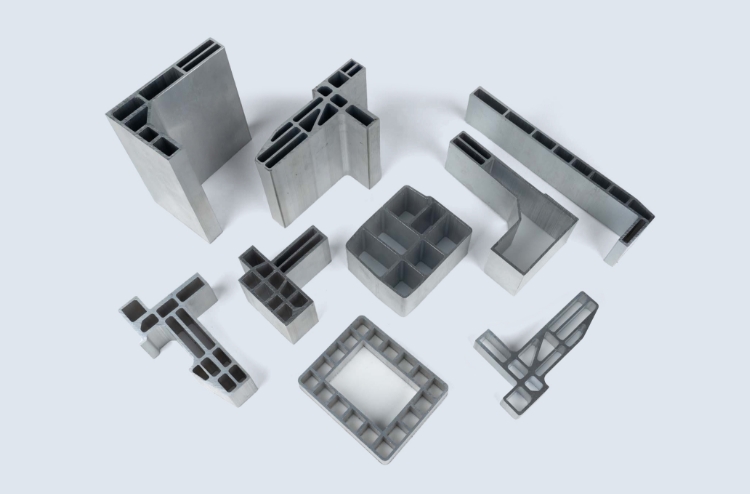

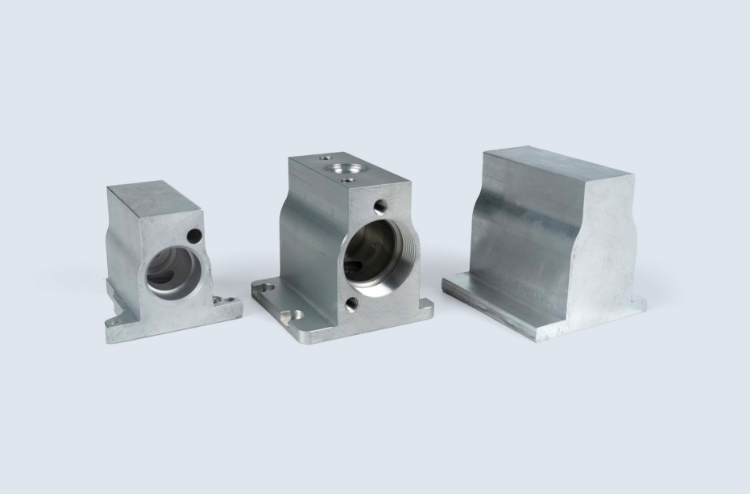

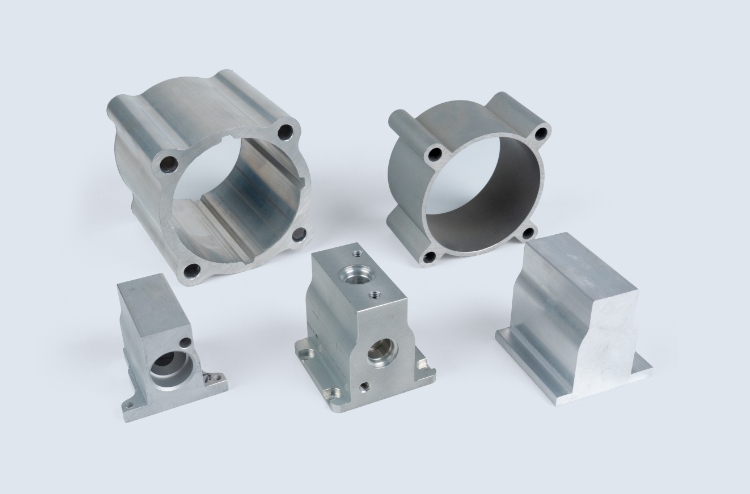

Hydraulic Motor

Pump Housing

- Material

-

A6061-T6

A6082-T6

A6110-T6

Cylinder Valve

- Material

-

A6063-T6

A6061-T6

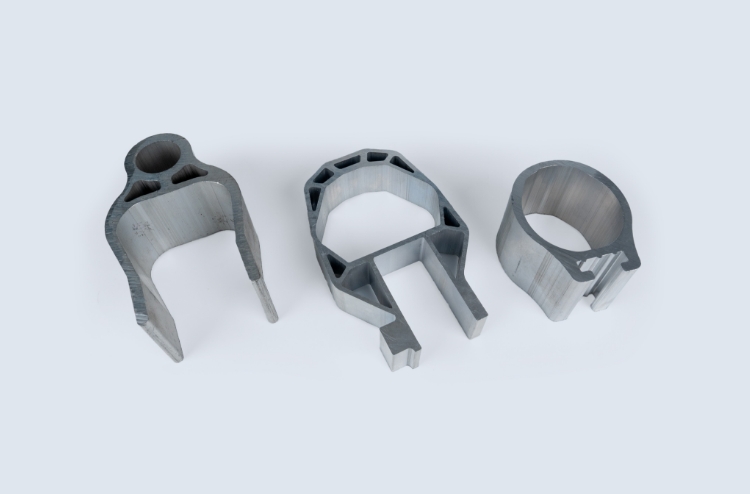

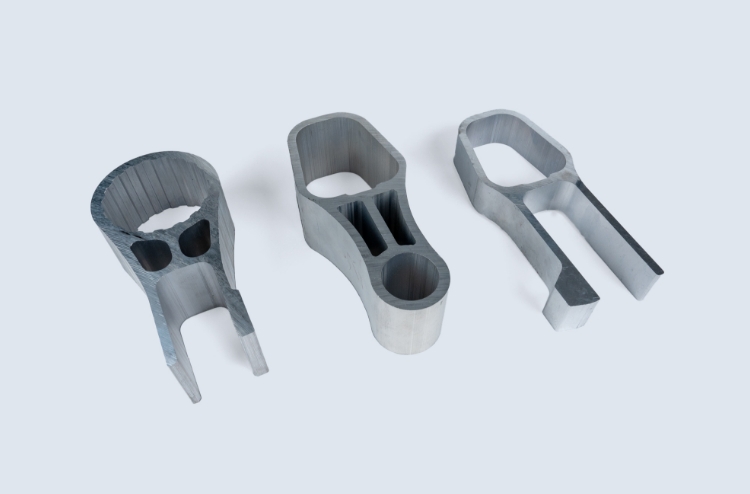

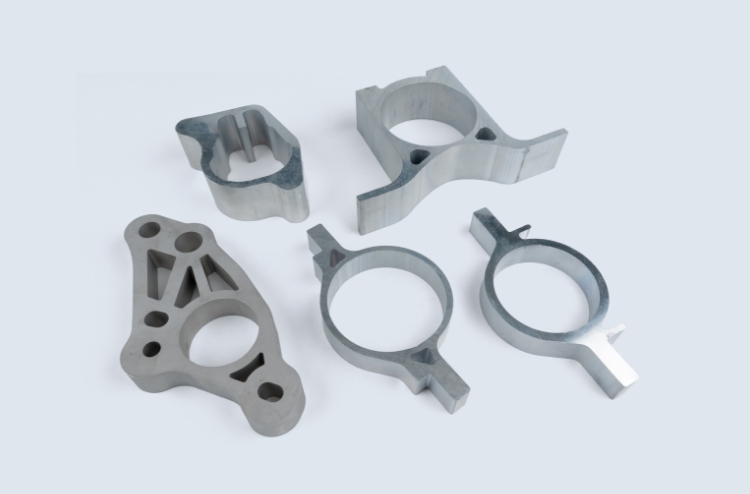

Bracket

- Material

-

A6063-T6

A6061-T6

A6082-T6

A6N01-T6

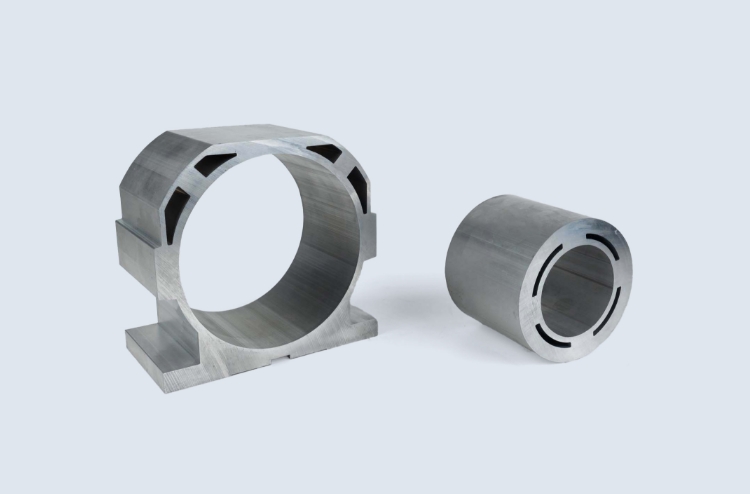

Motor Housing

for Generator

- Material

- A6063-T6

Do you need a specialized partner for aluminum processed products?

Get personalized guidance on custom aluminum products through a one-on-one consultation with Oneel.

Inquiry